A reader who recently watched “The Secrets to Creating an Effective Value StreamMap Webinar” asked when is okay to skip the current state map.

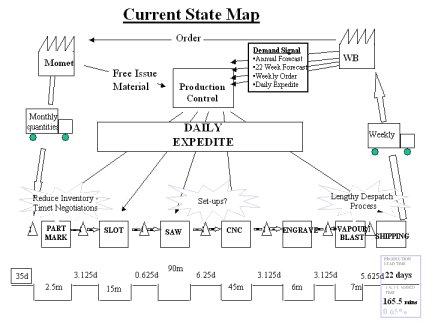

A

value-stream map is a visual depiction of the flow of materials and information

that provide the customer with a product or service. It also describes the lead

time of various operations and can be used as a starting point for analyzing

necessary activities and the amount of waste in the value stream. A current

state value-stream map depicts the current situation as is. A future state

value-stream map depicts what the value stream should look like after planned

improvements have been implemented. Value-stream mapping is a useful tool for

grasping the current situation and for planning improvements.

There

is a tendency to skip mapping the current state and go directly to the future

state map. But if we don’t understand the current process, we can’t really make

intelligent decisions about how the future current state might or should look.

A lot of companies want to skip the development of the current state map and

get right into brainstorming ideas for improvement. We must reduce this

impulse.

Skipping

the current state map is like building a house without surveying the land or visiting

the site. Doing so can lead to a home that

can’t be built and an upset homeowner.

The

key to creating an excellent current state values stream map is to document

what you actually see with your own eyes. We are not interested in how the

process is supposed to work, or was designed to work. Always collect

current-state information while walking the actual process to understand the

real flow. You will uncover more going to the Gemba.

Too

many Lean practitioners skip value stream analysis and jump right to identifying

specific sources of waste and removing them. Unfortunately, as they note, this

often results in local improvements, but rarely results in significant overall

improvements in the overall value stream or in improved products for customers.

To really have an impact, you need to begin by streamlining the entire value

stream, and only after that, drill down into specific processes to eliminate

waste.

The

current state allows us to “see” the waste which enables us to develop future

state value stream maps, identify opportunities for improvement, and initiate

improvement action plans. If you don’t do the Current State, you might never

find your waste and once you do one and find the waste, it give you a platform

for continuous improvement.

You can go fast and skip steps (then have to do it over anyway) or you can follow the process and do it right with results that are sustainable.

ReplyDeleteGreat post, Tim. I run into too many groups that don't want to map the current state or want to have one person do it and just verify it with the group (better than nothing, I guess). Groups need to understand where they are starting from before you can design any kind of future state.

ReplyDeleteIgnoring the current state is exactly what was preached in "Reengineering the Corporation." Companies ended up going into bankruptcy or losing a lot of money by doing this.

There is good in the current state. It must be understood so as to not repeat the past.

Michael Hammer later realized this and changed his opinion to needing to understand the current state.

Also, I have found the designing the future state and what needs to be done goes quicker when there is a deep understanding of the current state.

Skipping the current state is not much of a shortcut when you consider the lost learning. It is hard to improve something you don't understand. As is said, assumption makes a fool out of you and me. Use facts, collect direct information, and observe first hand the situation in front of you.

ReplyDelete