Just in Time (JIT), Continuous Improvement (CI) and Six Sigma are all systems that improve manufacturing quality and cut inventory costs. While there are loads of computer systems that are compatible with how these systems work, for inventory control, many companies prefer much simpler, manual whiteboard and card holder systems known as a Kanban system. Even large plants that could implement complicated electronic systems are opting to implement simpler Kanban Card Board Systems because they are easier to setup and use.

Kanban comes from a Japanese word meaning “card.” Today the term is in use by those in manufacturing worldwide. Manufacturers use Kanban systems to control work in progress (WIP) on production lines. Manufacturers use a Kanban system for making almost any product from baked goods to software to automobiles.

Kanban is a system that allows visualization of a task. Folks on the production line can see how they are doing. This feedback inspires and motivates those on the line. A Lean manufacturing coordinator in Lexington Kentucky uses Kanban boards and has high praise for its functionality:

“They are simple and effective for visual load leveling. We have them in our supply areas as well as each work cell. With the boards we always know which job we need to work on next … no time is wasted, we are always working the top priority order”

Kanban boards restructure and simplify the way communications take place on the factory floor. Hundreds of United States factories use the Kanban system, as excellent communications are an important part of any lean manufacturing process. Kanban Systems by Magnatag allows for simplified management of production and assembly tasks.

The following are some of the best advantages of using Kanban Card Boards

- Easy to setup, easy to use and easy to understand

- Flexible format can be used to show job priority, inventory levels and load leveling

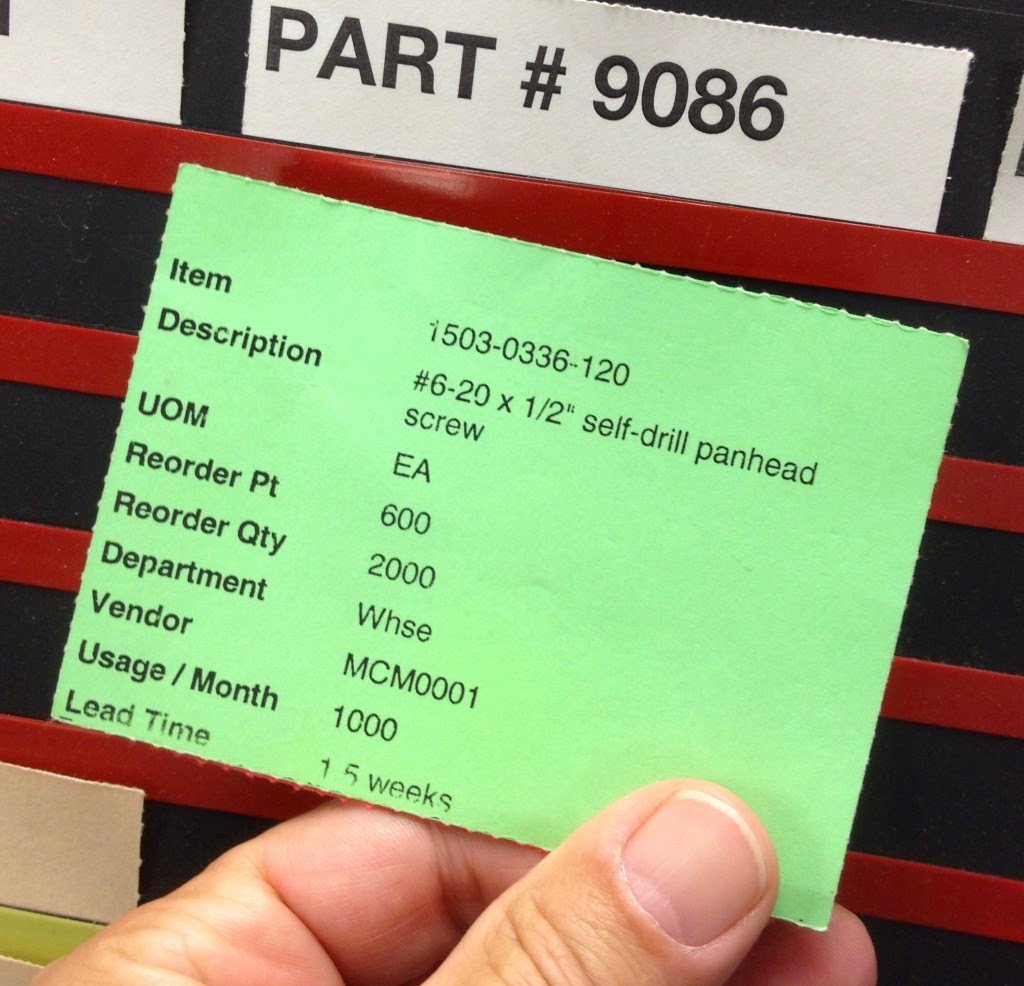

- Card Colors can be used to designate different types of materials and/or jobs

- Printable Cards can be customized to show lot numbers, job numbers, etc.

- Large and small capacity boards can be “right” sized for different applications

Prioritizing these tasks on the boards and in view of team members, contributes to efficiency, engagement, and team spirit – everyone knows the score in real-time as the tasks status are clearly visible as to status. In addition to managing production and assembly tasks, there are Kanban inventory boards, boards for job staging and much more.

About the Author:

Originally from the Cincinnati, Ohio area, Tom Shaw has an extensive background in working with both companies and individuals to solve scheduling, communication, productivity, and information display problems. After an extended tenure working with various manufacturers in Ohio, Shaw came to western New York to become a Visible Systems Specialist for Magnatag, a premier Whiteboard Source for over 48 years.

As a husband and father of two children, Shaw not only has an invested interest in communications and manufacturing, but also health and fitness, as he has a passion for running and training for marathons.

A Lean Journey

A Lean Journey

Leave a Comment

Your email address will not be published. Required fields are marked with *