Lean Tip

#3151 – Build a Culture of Continuous Improvement

Having a

lean and healthy culture requires many components. One of those is instilling

an environment of continuous improvement.

Gradual,

consistent change that sustains continuous improvement is critical. It doesn’t

mean you have to train staff in strict fundamentals. It does mean you need the

idea of continuous improvement to be part of everything you do.

Seek out

ideas about how to improve production processes. Making everyone part of the

change shows that you appreciate their opinions. It can also increase employee

engagement and foster a more inclusive environment.

Lean Tip

#3152 – Perseverance Should be Admired, But Only Up to a Point

If it

takes a lot of effort and time to prove your point, make sure it’s worth it –

for you and your sponsor. Persistence is an admirable quality and crucial to

success, but it’s important to know when to let it go and move on. You may

sometimes have to invest your passion in alternative projects to ensure long-term

success, so make sure you stay flexible.

Lean Tip

#3153 – Change of Behavior is as Important as the Tools

Industry

experts believe that change in behavior is mandatory for the effective

implementation of change. People have this tendency to work around a problem

rather than fix it, and this is where Lean and Six Sigma inculcate a

willingness to constantly address problems that arise in business processes.

When people are committed to changing their behavior even tools will be

incorporated seamlessly. Training your workforce in Lean and Six Sigma is one

thing, but without a change in behavior, the whole process will be just

academic without any practical implications.

Lean Tip

#3154 – Have the Right Measurement System in Place

Organizations

first need to understand that things that cannot be measured cannot be

improved. By having a proper measurement system in place, practitioners can

decide on baseline performance and use the data to make informed decisions. And

when people understand the potential of Lean and Six Sigma, there will be rapid

improvement in projects. Also by encouraging participants to define both

tangible and intangible measures one can monitor the impact of their

improvements and keep a database that will help in communicating the success to

the organization.

Lean Tip

#3155 – Have Constant Communication to Engage a More Employees

In an

organization, there can never be enough communication. There should be varied

communication channels to – receive information and comprehend it in a way that

the recipient will be able to reflect and act upon it. Having open

communication channels in an organization is an important aspect to complete

Lean and Six Sigma projects on time. On many occasions addressing a small group

or having face-to-face communication for discussion of important things is more

effective than mass e-mail communications. In fact, many organizations today

are using local displays with regular updates on work progress and visual

summaries of future plans or targets will help in better engagement of the

workforce.

Lean Tip

#3156 – Take a Lean Tour

Sometimes

we learn best by first witnessing the success of others. See the benefits of

lean in action. It is not difficult to find organizations that will allow you

to see their lean implementations (referred to as the Gemba walk). Take

detailed notes of what is highly effective in their Lean implementations, ask

questions, and get as much valuable information as you can in order to help you

formulate you own Lean strategy for implementation.

Lean Tip

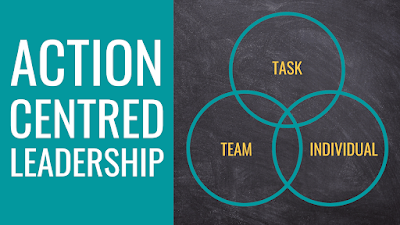

#3157 – Get the Whole Team on Board

To get

the greatest advantages out of Lean, the entire organization should adopt and

promote its practices, and extend its influence to suppliers as well. You must

involve the people who are the closest to the work and you must get support

from senior management as well.

Lean Tip

#3158 – Discard Conventional Fixed Ideas

Part of

problem solving is thinking “outside of the box.” Encourage fresh perspectives

and ingenuity in your team in order to develop innovative ways to forward Lean

manufacturing without changing what is already efficient and successful. With

such a rapidly evolving climate in manufacturing, sometimes conventional

thought is what leads to the problem in the first place!

Lean Tip

#3159 – Set Realistic Goals

In order

to get people motivated, they must value the goals set for Lean manufacturing.

These goals must be challenging, yet obtainable for your employees. Further,

always ask for feedback on these goals, as well as progress toward target

attainment. Feedback should always contain measurable facts and figures.

People,

by nature, are goal-oriented and want to see that their actions are producing

positive results. But if you’re not being realistic with your target goal

dates, you are setting yourself up for failure from the beginning. Set small

goals and reward yourself and your employees for each milestone accomplished.

Lean Tip

#3160 – Show Results, Not Action Items

Naturally,

implementation is what ultimately yields results and improvement. The last

think you want is to devise and formulate a Lean campaign that then sits on the

shelf and collects dust.

It’s

important that you post real results on your Lean board, not things that you’re

going to do. You must be able to point out your successes if you are ever going

to convince others that Lean really works.

By

concentrating on the processes and building continuous improvement, you will

have the culture change that you are looking for. Also, correct mistakes

immediately. Don’t wait for the next shift, the weekend or maintenance to do

it.

Lean Tip

#3161 – Make Experimentation a Habit

Today’s

changing times make it essential for big and small companies to be able to

adapt and – if necessary – pivot quickly. Any firm that keeps the focus on

experimentation welcomes new ideas and works on evolution patterns to see what

their product or service could become. But a culture where experimentation

thrives often takes a push from management to make it happen.

Lean Tip

#3162 – Ensure a Strong Commitment From the Leadership Team

It’s

important to develop a strong commitment to the change amongst the senior

leadership team before it is rolled out company-wide. In doing this, you can

identify any potential obstacles or resistance to change and put a plan in

place to overcome these. The top executive should be the main driving force,

and the responsibility of cascading the change further will be down to the

senior leadership team so it’s crucial to instill a high level of

understanding.

Lean Tip

#3163 – Engagement is Everything

Don’t

underestimate the power of engagement here. Change requires engagement to

succeed. Highlighting employee strengths and where these can be put to

effective use within the change itself will move focus away from resistance

towards more positive actions.

Lean Tip

#3164 – Identify Key Influencers

Identify

any informal leaders within the business and ensure they are a champion for

change. Find out who the company’s sounding-boards are and make sure these

people are on-board with the change!

Recognition

is powerful. You could create an internal campaign to identify those who are

quick to adapt to the change and show leadership qualities in their positive

adoption.

Lean Tip

#3165 – Constant Assessment

When you

are supporting your senior leaders to adapt to change and form new habits,

encourage them to consider the overall objective you are trying to achieve

through the change and motivate them through outcome thinking.

Regularly

assess these new habits and how the change is being adopted throughout the

business. What’s working, what’s not? How can these challenges be confronted

and overcome?