There is no

room for compromise in Lean when it comes to quality. We have to learn to build

quality into our processes and design Lean processes based on right-first-time

principles.

Building

quality into our processes means not simply relying on perfectly trained

individuals and teams who never make mistakes. Standard Operating Procedures

may help people making errors, but it does not stop them.

We have to

assume, just like in Murphy’s Law – that anything that can go wrong will go

wrong … eventually. And by accepting this fact, the most important aspect of

our processes is how well we design them to eliminate any potential errors from

ever occurring.

Lean is about

stopping and fixing issues when they go wrong: quickly and consistently, every

time. It is about creating the proper workplace setup, to ensure that when

things go wrong, we can identify them quickly.

Jidoka is an

integral part of Lean principles that focuses on optimizing the flow of

production processes. It plays a crucial role in helping organizations become

more efficient and productive by reducing waste, enhancing quality, and

increasing customer satisfaction. Jidoka is based on the idea that any defect

should be detected immediately so the process can be stopped until the root

cause of the problem is identified and corrected. This helps eliminate wasted

time, resources, and energy from running defective parts through a production

line.

The

implementation of Jidoka relies on a mix of cultural concepts and Lean tools

that are summarized below.

Developing a

Jidoka mindset. Many

people are trained to react to problems and to put in place quick fixes. The

concept is to keep things running for as long as possible and work around

problems as quickly as possible. A Jidoka mindset is different in that it says

that, in the long run, efficiency will come from addressing the root cause of

problems and that investing time in solving problems is a valuable investment.

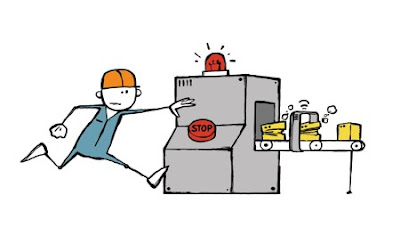

Empowering

staff to ‘stop the line’. Do

your staff feel that they are empowered to say ‘stop’ when they see an unsafe

act or a problem occurring? Many organizational cultures, through the words and

actions of managers, disempower staff from stopping a process. Developing a

culture where people feel that they are able to raise a real issue – and that

far from being penalized they will actually be thanked for raising the issue –

is very important in jidoka.

Installing

andons. Andons are

audible, or more commonly visual, signals that something has happened.

The aim is that andons quickly alert managerial and technical staff to a

problem having arisen so that they can get to the source of the problem and

begin to investigate it.

Solving the

root cause. Quick

fixes are typically just that. Jidoka relies on the implementation of an

immediate fix to stem the potential damage and on the longer-term fix that

comes through root cause analysis.

Utilizing

standard work. Having

implemented the changes it is vital to document what has been done and to carry

out any training required on the new process.

Selective

automation. Selective

automation is about investing in technology to detect – and more ideally

prevent – errors arising wherever there is a business case to do so. This means

wherever there is either a high probability that things will repeatedly go

wrong, or where a problem arising has significant impact (such as the ability

to cause harm), then it means investing in sensors and other systems to enable

you to control the process and detect problems as early as possible.

By not fixing

the problem as soon as it is identified increases the costs of fixing it later.

It potentially allows the problem to get to the customer and kills causing even

more damage to the business. And really importantly, in a culture of continuous

improvement, we want to learn fast.

If the issue is

not addressed immediately, we miss the opportunity to learn (kaizen) and when

we finally do get around to fixing the issue, we might find we don’t just have

one product that has failed but multiple products.

The sooner the

problem is detected, the easier it is to fix and the smaller the impact. Thus, one of the important parts of Lean is

to be able to detect problems, raise them quickly, analyze and fix.

A Lean Journey

A Lean Journey

Leave a Comment

Your email address will not be published. Required fields are marked with *