Visual

inspection, especially 100% visual inspection, is used by many industries as

part of their Quality or Risk Management programs. Sometimes, as the last

resort, companies implement 100% inspection if the residual risk is deemed to

be high.

Juran, one of

the giants of Quality, has written that, based on his studies performed on

Inspector accuracy, 100% inspection is about 87% effective. Juran gave the

following formula to calculate the Accuracy of an Inspector.

Accuracy of

inspector = percent of defects correctly identified = (d-k)/(d-k+b)

where d = defects reported by the inspector

k = number of

good units rejected by the inspector

d-k = true

defects found by the inspector

b = defects

missed by the inspector, as determined by check inspection

d-k+b = true

defects originally in the product

This brings us

to the next question, is 200% or 300% inspection effective?

From a pure

probability standpoint, multiple inspections are indeed effective. For example,

if we determine that 100% inspection is 85% effective (as an example), we can

then calculate the probability of rejects being identified by at least one

inspector.

P(rejects being

identified by at least one inspector) = 1 – (1- e)^n

where e = inspection effectiveness (85% in the

example)

n = number of

100% inspections (3 in the example)

Thus, we can

determine that the 300% inspection with an inspection effectiveness value of

85% is 99.7% effective. In other words, 300% inspection will still result in

0.3% of the bad product to be missed.

The number of

rejects caught by 100% inspection can be found by the following calculation.

# of rejects

caught = N * p * e

where N = Lot size

p = %

non-conforming product

e = inspection

effectiveness

The least

effective form of quality control is that of inspection by people, people are

fallible and can often fail to observe problems especially if the work is

repetitive and the shift is long. Consider the common exercise often used in

demonstrating the weaknesses of 100% manual quality inspection. Count the

number of F’s in the paragraph below:

THE NECESSITY

OF TRAINING HANDS FOR FIRST-CLASS FARMS IN THE FATHERLY HANDLING OF FRIENDLY

FARM LIVESTOCK IS FOREMOST IN THE MINDS OF FARM OWNERS. SINCE THE FOREFATHERS

OF THE FARM OWNERS TRAINED THE FARM HANDS FOR THE FIRST-CLASS FARMS IN THE

FATHERLY HANDLING OF FARM LIVESTOCK, THE OWNERS OF THE FARMS FEEL THEY SHOULD

CARRY ON WITH THE FAMILY TRADITION OF TRAINING FARM HANDS IN THE FATHERLY

HANDLING OF FARM STOCK BECAUSE THEY BELIEVE IT IS THE BASIS OF GOOD FUTURE

FARMING.

How many did

you get?

There are 48

f's, however most people will not get the right answer; their answers will vary

between about 30 and 60 letter “f”s in the paragraph having missed letters or

double counted.

W. Edwards

Deming suggested that inspection is too little too late: "Cease reliance

on mass inspection to achieve quality. Eliminate the need for inspection on a

mass basis by building quality into the product in the first place."

He didn't call

for the elimination of inspection altogether, but rather for its reduction to

the optimal level. Some inspection is always necessary and is an important tool

for gathering data about what you are doing. But 100 percent inspection is

seldom appropriate and is costly in both time and money. And most important,

inspection cannot always catch problems that are inherent in the system itself.

Rafael Aguayo,

author of Dr. Deming: The American Who Taught the Japanese About Quality, makes

this point vividly in his book: "The disastrous explosion of the space

shuttle Challenger was apparently due to the failure of rubber O rings. The

rings in the Challenger were within specifications. No amount of inspection

would have prevented them from being used. But the rings tended to fail in

extreme cold. It was only a matter of time before a tragedy occurred.

Inspection cannot improve the level of quality that is designed into the

product."

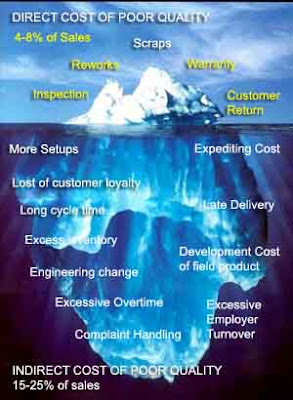

Too much

reliance on inspection also supports a "blame the worker" mentality

that is antithetical to today's understanding of what drives quality

improvement. The health care field is richly populated with individuals who are

highly committed to doing the right thing for their patients, no matter what is

required. But even extraordinary people cannot consistently rise above a system

that is poorly designed.

When

organizations work to improve processes and systems, the opportunities for

"defects" to occur are systematically reduced. Inspection then

becomes useful as a means of gathering data to drive further quality

improvement efforts, rather than a hunt for mistakes and those responsible for

them.

Harold F.

Dodge, principal architect of statistical quality control, has stated that “You

cannot inspect quality into a product.” The feedback loop should be as small as

possible for an inspection activity to be value adding. This feedback also has

the benefit of improving the process since the operator is made aware of the

issue almost immediately. The best case is to have poke-yoke or mistake

proofing such that mistakes do not happen at all.