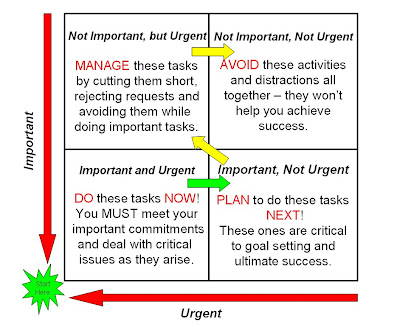

In a previous post I discussed a formula for success that prioritizes tasks by the Urgency and Importance of the task. I am typically one that uses a list type of priority system arranging my tasks in order of highest priority to lowest. Occasionally, I will hand write a “To-Do” list but it is often electronic in the computer and on my handheld device. Recent posts on various visual boards like Jon Miller’s agile board or Xavier Quesada Allue’s kanban board have inspired me to try my own visual board.

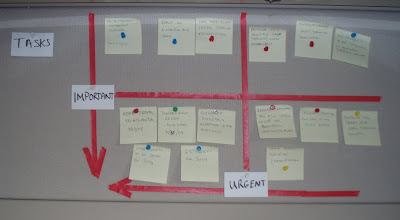

I modified the Important and Urgent axis of the Covey matrix so that the highest priority and most urgent tasks would be closest to me. Below is a pictorial of this modified board.

I work from the lower left quadrant to the low right quadrant tackling the most timely and most important tasks. Then I can move to less important but urgent tasks.

I work from the lower left quadrant to the low right quadrant tackling the most timely and most important tasks. Then I can move to less important but urgent tasks.

With my old priority system of listing my tasks some of the lower priority items may stay on the list for awhile never really moving. This new system makes you realize those items fit into the upper right quadrant and that these are tasks that should be avoided.

This is the first version of this board. Like everything in Lean this to will be improved.

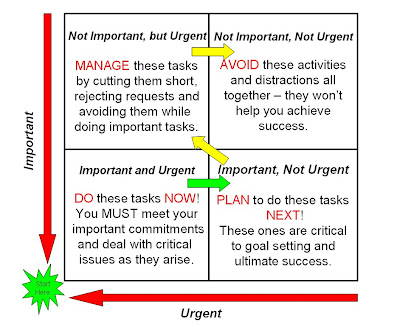

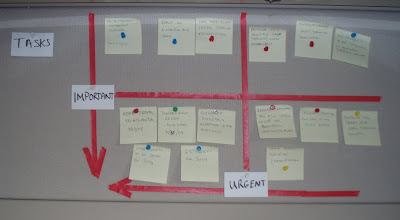

I modified the Important and Urgent axis of the Covey matrix so that the highest priority and most urgent tasks would be closest to me. Below is a pictorial of this modified board.

I work from the lower left quadrant to the low right quadrant tackling the most timely and most important tasks. Then I can move to less important but urgent tasks.

I work from the lower left quadrant to the low right quadrant tackling the most timely and most important tasks. Then I can move to less important but urgent tasks.With my old priority system of listing my tasks some of the lower priority items may stay on the list for awhile never really moving. This new system makes you realize those items fit into the upper right quadrant and that these are tasks that should be avoided.

This is the first version of this board. Like everything in Lean this to will be improved.

So far this does help to manage tasks in a visual manner. Next, I will have to create a standard method to review and update this board. Tasks may change in importance and urgency with time. Right now I am reviewing tasks on Mondays to prepare my week for the most success.

What ways do you manage your activities for success?

What ways do you manage your activities for success?