How to Get Started with Improvement in Your Organization

- Lean Basics

- September 17, 2025

At first glance, the “hero” mentality might seem like a workplace virtue. It’s the employee who takes charge in every crisis and seemingly save the day when systems fail. The organization’s heroes put in the long hours to get the job done – because, and often ostensibly, because others in the organization do not have

READ MORE

Discovering ways to improve a company provides the opportunity to increase productivity and raise profitability. As a manager, decision-maker or team leader, identifying areas for improvement within your organization is an effective way to make it more successful. Improvements can cover a range of benefits, including increased efficiency, decreased spending and higher customer satisfaction levels.

READ MORE

The other day I was asked about the benefit of cellular manufacturing so I thought I would share some of my thoughts with you. Cellular manufacturing is a manufacturing process that produces families of parts within a single line or cell of machines operated by machinists who work only within the line or cell. A

READ MORE

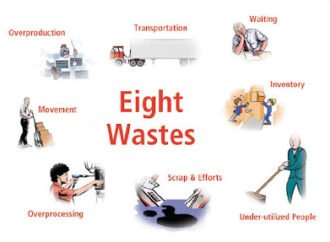

DOWNTIME and the Eight Wastes in Lean Manufacturing Acronyms are powerful tools for remembering important concepts, objectives, and processes. In Lean manufacturing, one of the most effective acronyms is DOWNTIME, which represents the Eight Wastes. These wastes highlight the distinction between value added vs non-value added activities and provide a framework for process improvement. The

READ MORE

Lean Manufacturing is a business improvement philosophy that has developed over many years (as well as a collection of lean manufacturing tools), it is a method to better focus your business on the true needs of the customer to help you prevent waste from being built into your system. When properly implemented, lean manufacturing provides

READ MORE

Lean manufacturing is the continuous improvement methodology of choice for companies around the world. It’s a people-oriented practice that focuses on reducing production lead times within your operations. These practices create a framework that emphasizes eliminating activities that do not add value for the customer, and focuses on reducing cycle, flow, and throughput times. These

READ MORE