How to Get Started with Improvement in Your Organization

- Lean Basics

- September 17, 2025

A couple days ago I posted an article on standard work as a mechanism for facilitating and empowering improvement. By documenting the current best practice, standardized work forms the baseline for kaizen or continuous improvement. As the standard is improved, the new standard becomes the baseline for further improvements, and so on. Improving standardized work

READ MORE

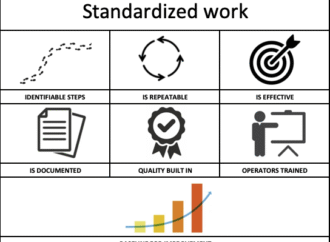

Standard work is a written description of how a process should be done. It guides consistent execution. At its best, it documents a current “best practice” and ensures that it is implemented throughout a company. At a minimum, it provides a baseline from which a better approach can be developed. The definition of standard work

READ MORE

The Lean business process improvement methodology is a way of planning and measuring the long-term success in our organization, focused on improving safety, quality, delivery, cost, and employee morale. It seeks to eliminate waste and streamline the delivery of value to the customer. There are dozens of tools associated with the practice of Lean, such

READ MORE

The most successful companies are never satisfied with the status quo. They constantly have their eye on the next innovation, the next level of performance. They know the importance of continuous improvement in all areas of the business. Even if things are going really well, people at successful organizations are looking at what could be

READ MORE

Admit it or not, all companies face challenges. In today’s competitive market, Lean is turning out to be “the solution” to manufacturing industries across the spectrum for survival and success. Lean manufacturing helps organizations to achieve targeted productivity and more by introduction of easy-to-apply and maintainable techniques and tools. Its focus on waste reduction and

READ MORE

There is little doubt that engineers and designers are well aware of the need to minimize cost, and in most instances, they are anxious to receive and use better cost information. However, there are other reasons why unnecessary cost occurs in the products they are specifying. The most frequent reasons unnecessary cost is found in

READ MORE