Celebrating National Manufacturing Week: Advancing Lean and Inspiring Future Makers

- In the News, Lean in Practice

- December 29, 2014

Fear of failure is one of the greatest fears people have. It is a genuinely scary thing for many people, and often the reason that individuals do not attempt the things they would like to accomplish. But the only true failure is failure to make the attempt. If you don’t try, you gain nothing, and life

READ MORE

A common question by those just starting down a Lean journey is how do you find time for improvement. “You will never find time for anything. If you want time you must make it.” – Charles Buxton (Philanthropist and Politician) It is an age-old battle — production time versus improvement time. Two worthy rivals attempting

READ MORE

When I am not at work (as a Quality Manager) and not writing articles for this blog I spend a great deal of time coaching youth ice hockey. This past weekend our season came to an end with the completion of playoffs. As a Lean leader often does I took some time to reflect on

READ MORE

Some may say that it’s impossible to eliminate mistakes. And they are right; it is, most of the time. But, to be honest, they are missing the point. Poka yoke, or mistake proofing, describes any behavior changing constraint that is built into a process to prevent an incorrect operation or act occurring. The three aims

READ MOREOn The Lean Edge Blog this week a reader asked how to take Lean into product development: A consumer-products company has recently begun its Lean journey by focusing on Lean fundamentals starting on the shop floor (standard work, 1-piece flow, pull, work to Takt). The company is simultaneously refreshing its product portfolio. Although the cross-functional

READ MORE

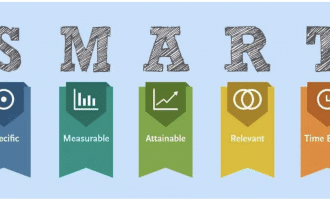

Accurate problem statements save time and effort by focusing the team on root cause identification. A well-stated problem statement is a clear and concise statement that describes the symptoms of the problem to be addressed. It speeds a robust corrective action process by identifying potential root causes and eliminating bias and noise. Unfortunately, many don’t

READ MORE