Keep Calm and Carry On: How to Engage With Your Customers

- Engagement, Lean Basics, Lean in Practice

- April 15, 2020

The overriding goal of cycle time reduction is total customer satisfaction. Changes in areas to reduce cycle time should result in improved operation of the cycle, given current resources, technology, and capital. These should set the stage for continuous improvement. There are nine phases in cycle time reduction efforts: Phase 1: Identify Critical Business Issue

READ MORE

Total Cycle Time is the actual time elapsed from when a customer expresses a need for a product until customer’s need is satisfied. It includes all the time spend by managers in directing the business, by office personnel in handling and processing the paperwork, by engineers in creating and developing new products and technologies, by

READ MORE

Many business leaders envision lean initiatives as massive endeavors that require long training sessions, big meetings, and complete overhauls. Yet the reality is that some of the most successful lean initiatives begin with a commitment to creating a culture that’s focused on small, continuous improvements. It’s the only way to achieve the long term company

READ MORE

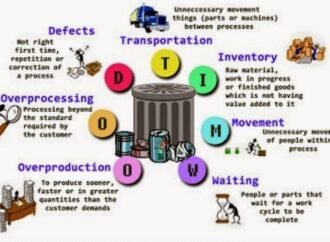

When thinking Lean, you should always be thinking about waste. Each business potentially has 7 Deadly Wastes according to Lean thinking. The 7 wastes are:• Defects• Overproduction• Transportation of product• Waiting• Inventory• Motion of people• Processing Students participating in a education program at IDEXX Laboratories made a video to illustrate the 7 wastes. This video reminds me

READ MORE

A recent fortune cookie fortune reminded me of an important Lean lesson. The fortune says: “The best angle from which to approach any problem is the TRYangle.” I’ve learned at Wiremold, originating from Art Byrne, the fundamentals of trystorming. This method consists of, “Rapid cycles of real-time experimentation, used to test and adjust improvement ideas

READ MORE

Jidoka is very popular with the product quality inspectors, who check items at the end of the production process. That’s because Jidoka ensures that a defect is identified and corrected immediately and not at the end of the process. This, therefore, reduces the pressure on a process engineers relying on final inspection. So what happens

READ MORE