Ron Pereira at the LSS Academy shared a great example of an inexpensive visual control using plastic cups. This has inspired me to share a kanban system employed in one of our factories that utilizes golf balls.

As inventoried product is consumed by the customer a card signal is sent to a processing area to consume a buffer inventory to replace the finished goods product. Upon relieving this buffer inventory a kanban (golf ball) is sent to the upstream process to replenish this buffer.

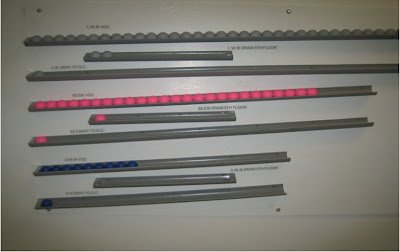

The golf ball is returned to the upstream process via a pipe in order of the customer demand and hence priority of replenishment is in FIFO (First-in, First-out) order.

The golf balls can then be staged as shown above according to what product type is running on the process equipment or manufacturing cell. The golf balls are returned with the product to the down stream buffer inventory location via simple slide.

Ping pong balls and pvc pipe can also make other effective visual control systems like this one.

You don’t need elegant computerized kanban solutions. Golf balls, ping pong balls, and some pipe can create quick efficient methods to manage your operations. These visual aides also allow everyone to “see” and interact with the system.

A Lean Journey

A Lean Journey

Leave a Comment

Your email address will not be published. Required fields are marked with *