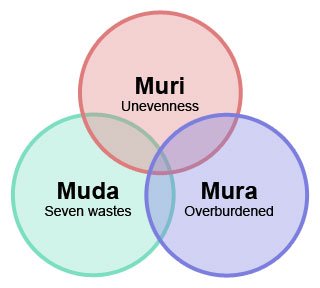

In today’s economy many companies are looking for cost savings. Eliminating muda (waste) is the focus of most lean manufacturing efforts. But two other M’s are just as important to making lean work. In fact, focusing on only the eight wastes of muda can actually hamper productivity. Lean is about the elimination of muda, muri, and mura.

wastes

Systems that have starts and stops, overutilization then underutilization, do not lend themselves to quality, standardization of work, productivity, or continuous improvement. Taiichi Ohno explains this point from the tortoise and the hare fable:

The slower but consistent tortoise causes less waste and is much more desirable than the speedy hare that races ahead and then stops occasionally to doze. The Toyota Production System can be realized only when all the workers become tortoise.

You can start eliminating muri and mura in your process today through the same observations for eliminating muda. As you watch your process try to understand what is happening to cause the fluctuations resulting in the unevenness. Look for signs of overburdening people physically (muscles tightening, gripping tightly, straining, excessive reaches, and others) and mentally (watch employees’ eyes, frowning, squinting).

As you look for more gains in your process don’t focus just on muda but all three M’s. Hopefully with your new eyes for improvement you will not forget the other M’s. Muda, Muri, and Mura are all interconnected and eliminating all sources of inefficiencies will produce the most gain.

A Lean Journey

A Lean Journey

Leave a Comment

Your email address will not be published. Required fields are marked with *