Keep Calm and Carry On: How to Engage With Your Customers

- Engagement, Lean Basics, Lean in Practice

- April 15, 2020

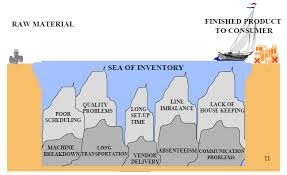

One of the most misunderstood aspects of Lean is the use of inventory. Inventory is one of the eight deadly sins (wastes) in Lean manufacturing. This waste is often one that hides other wastes in our businesses. I think most are familiar with the river and boulder analogy. The water level in the river is

READ MORE

A reader who recently watched “The Secrets to Creating an Effective Value StreamMap Webinar” asked when is okay to skip the current state map. A value-stream map is a visual depiction of the flow of materials and information that provide the customer with a product or service. It also describes the lead time of various

READ MORE

In manufacturing, changeover is the process of converting a line or machine from running one product to another. Changeover times can last from a few minutes to as much as several weeks in the case of automobile manufacturers retooling for new models. Reducing changeover time is like adding capacity, increasing profitability and can help most

READ MORE

A Lean Enterprise is centered on the concept of flow. Once value added activities and necessary non-value activities are identified, improvement efforts are directed toward making the activities flow. Flow is the uninterrupted movement of product or service through the system to the customer. An obvious question is why the processes we operate at the

READ MORE

The importance of the quality function within the organization has been evolving along with that of the customer. Organizations focused on their customers consistently outperform their competition. A truly customer-focused organization sees things through the “lens of the customer” not the “lens of the organization”. Customer-driven organizations share certain traits. Flattened hierarchies. When customers are

READ MOREWhen you ask a number of people to explain Lean Manufacturing in one sentence, most of them will answer: “eliminate waste”. The reason is that eliminating waste, or Muda is a relatively easy way of identifying the low hanging fruits for improvement in an organization. However, Muda is not the only ‘M’ Toyota has built

READ MORE