Quality

- Home

- Quality

Five Guidelines on Effective 5 Why Analysis0

- Problem Solving, Quality

- June 11, 2018

Asking why 5 times: “the 5 Whys”, is a simple but powerful tool to use with any problem solving activity. It’s a technique to help you get past the symptoms of a problem, and to find its root causes. Simply ask the question “why” up to five times. Sakichi Toyoda, one of the fathers of

READ MORE

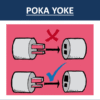

Seven Best Poka-Yoke Devices0

- Lean Basics, Quality

- August 8, 2016

Generally the most effective way to achieve quality is to avoid having defects in the first place. It is much less costly to prevent a problem from ever happening than it is to find and correct the problem after it has occurred. Focusing on prevention activities whose purpose is to reduce the number of defects

READ MORE

Reprise: The Seven Basic Quality Tools0

- Quality

- July 11, 2016

Pascal Dennis recently said that the so-called ‘Seven QC Tools’ aren’t second nature to everybody. I couldn’t agree more with Pascal. In that spirit, I’ll describe these core tools & how they can help. The Seven Basic Tools of Quality is a designation given to a fixed set of graphical techniques identified as being most helpful

READ MORE

Problem Solving Starts With Defining The Problem0

- Problem Solving, Quality

- July 13, 2015

Accurate problem statements save time and effort by focusing the team on root cause identification. A well-stated problem statement is a clear and concise statement that describes the symptoms of the problem to be addressed. It speeds a robust corrective action process by identifying potential root causes and eliminating bias and noise. Unfortunately, many don’t

READ MORE

Quality is Defined by Customer0

- Quality

- July 6, 2015

Like beauty and truth, quality is in the eye of the beholder, your customer. Quality is an ever evolving perception by the customer of the value provided by a product. It is not a static perception that never changes but a fluid process that changes as a product matures (innovation) and other alternatives (competition) are

READ MORE

Guest Post: GM Ignition Switch Recall vs. Sunroof Recall: An ISO 9001 Case Study0

- Guest Post, Quality

- May 18, 2015

Today I am pleased to be able share a guest post sponsored by one of our sponsors 9001 Academy. This post compares two product recalls in terms of a quality management system. Product recalls are something we have become used to in our society. As I argued in my article Does a QMS ensure 100%

READ MORE

Latest Posts

-

100% Final Inspection is Not 100% Accurate

- Quality

- December 4, 2024

-

How Effective is Your Poka-Yoke?

- Quality

- June 17, 2024

-

-

A Lean Journey

A Lean Journey