Blog

- Home

- Blog

Lean, Visualization, and Current Events0

- In the News, Lean in Practice, Visual Factory

- July 10, 2009

I was watching Fox News the other day and they had a story called “Health Care Reform Visual”. They highlighted a video that Matthias Shapiro did using pennies to visual the financial numbers being talked about with Health Care Reform. Now you might say, what does this have to do with Lean? Well, the answer

READ MORELSS Academy Guide to Lean Manufacturing0

- Lean Resources

- July 8, 2009

I believe those in the Lean community who are practitioners and educators are always learning from our own experiences and from others. There is great benefit in sharing what you have learned along the way with others. It is from this activity real learning, reflection, and improvement takes place. Ron Pereira from LSS Academy has

READ MORE

Simple Kanban with Golf Balls0

- Lean Basics, Sharing Best Practices, Visual Factory

- July 6, 2009

Ron Pereira at the LSS Academy shared a great example of an inexpensive visual control using plastic cups. This has inspired me to share a kanban system employed in one of our factories that utilizes golf balls. As inventoried product is consumed by the customer a card signal is sent to a processing area to

READ MORE

Is the glass half full or half empty?0

- Lean Basics

- July 5, 2009

I was with a consultant the other day doing a training event and he said to a small group of us that he had a simple Lean definition. He drew a picture on a piece paper of a glass of water like this He asked “Is the glass half full or half empty?” The optimists

READ MORE

Use of Name Tokens on a Shared Shadow Board0

- Lean Basics, Sharing Best Practices, Visual Factory

- June 27, 2009

As part of this journey to find “True North” it is important to share best practices. A common saying in the Lean community is to “steal shamelessly”. We often follow this up with “adopt then adapt”, meaning to implement improvement then work to improve said improvement. Recently, I observed an activity that is worth sharing.

READ MORE

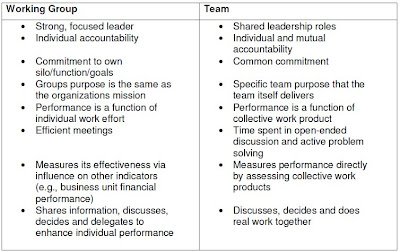

Not All Groups are Teams0

- Lean Management

- June 24, 2009

Highly empowered and effective teams are the key to compete in today’s world of high technology processes, six sigma quality and continuous innovation. We have all heard the adage that “There is No I in Team” but what does that really mean? A group is two or more people who interact with each other to

READ MORE

No “Fat” Behavior, Please0

- Lean Basics, Lean Management

- June 20, 2009

Transforming a traditional organization to a lean organization is about creating a cultural change. The only way to create a sustainable cultural change is to change behavior. Many lean initiatives have failed from complications in changing behavior. Bob Emiliani who has studied lean transformations and lean behaviors was the first to use the term “fat”

READ MORE

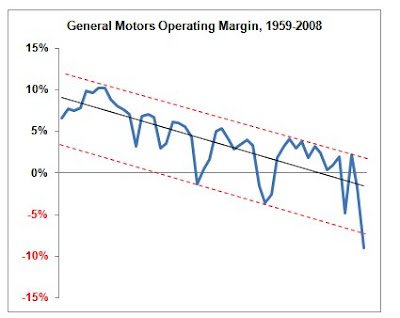

Is it the End of an Era or Just another Lesson?0

- In the News, Lean Basics

- June 17, 2009

With the recent bankruptcy of General Motors, Jim Womack wrote a letter on The End of an Era. Womack is considered one of the originators of Lean Thinking in the US from studying Toyota in the 1980’s. His first book the Machine that Changed the World is the first books I ever read on Lean.

READ MOREGemba Academy – A Source of Learning0

- Lean Resources

- June 16, 2009

The Gemba Academy provides high quality online video training for individuals and groups. They currently have the School of Lean but will add later this summer the School of Project Management and the School of Six Sigma. We learned at the Gemba, or the place the work is done, and now we want to help

READ MORE

A Lean Journey

A Lean Journey